Maximizing Rubber Fender Durability: A Comprehensive Guide for Professionals

- mahameruputra indonesia

- Aug 22, 2024

- 2 min read

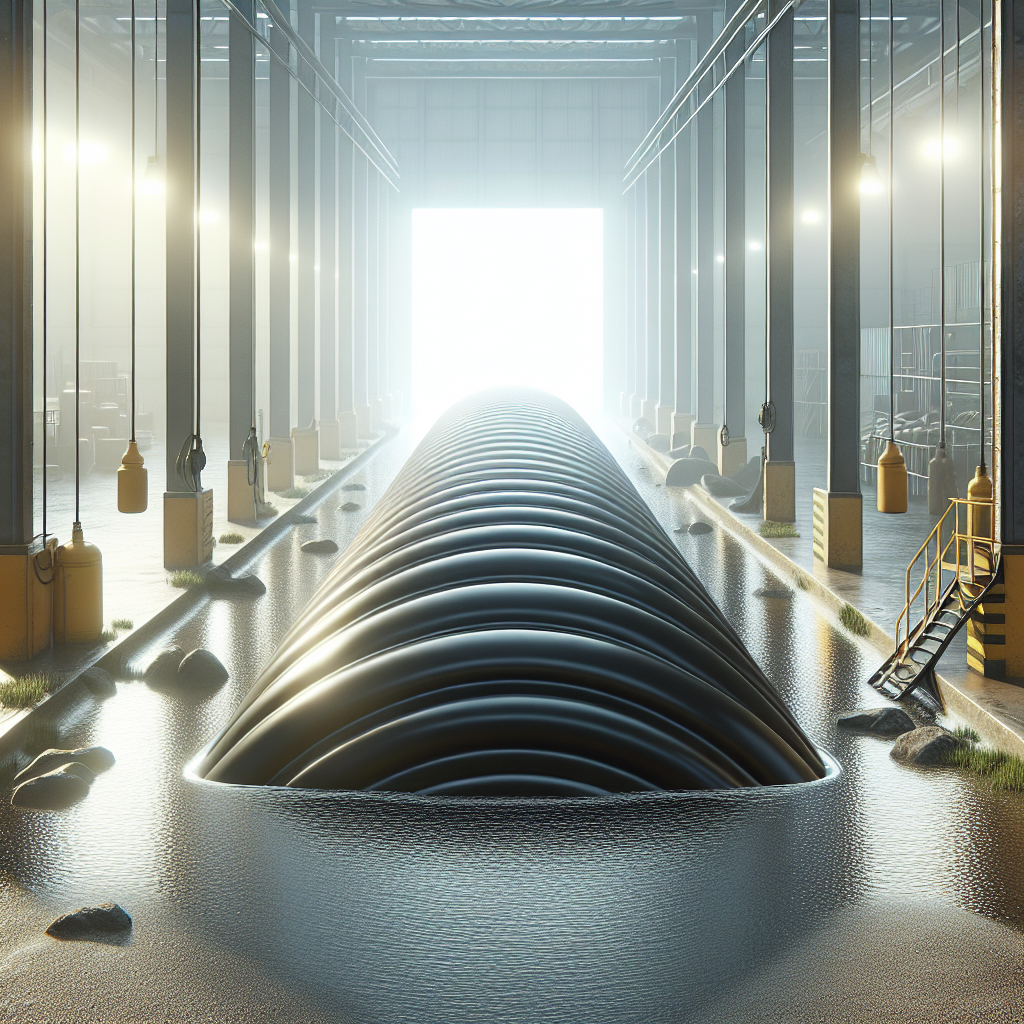

In the maritime industry, the importance of rubber fenders cannot be understated. These critical components play a pivotal role in protecting vessels, docks, and other maritime structures from damage during mooring and berthing operations. As professionals working in this sector, ensuring the durability and longevity of rubber fenders is paramount to maintaining operational efficiency and safety standards. In this editorial piece, we delve into the strategies and best practices for maximizing rubber fender durability, providing you with valuable insights to enhance your operations.

Understanding Rubber Fender Composition and Function

Before delving into durability-enhancing techniques, it is crucial to grasp the composition and function of rubber fenders. These resilient structures are typically made from high-quality rubber compounds that exhibit exceptional strength and elasticity. The primary function of rubber fenders is to absorb kinetic energy during vessel impact, thereby preventing damage to both the vessel and the structure.

Factors Affecting Rubber Fender Durability

Several factors can influence the durability of rubber fenders, including environmental conditions, maintenance practices, and operational parameters. Exposure to harsh weather conditions, UV radiation, and high temperatures can accelerate the deterioration of rubber compounds. Furthermore, improper storage, infrequent inspections, and inadequate maintenance can compromise the integrity of rubber fenders, leading to premature failure.

Proactive Maintenance Strategies

To maximize the lifespan of rubber fenders, proactive maintenance is essential. Implementing regular inspection schedules to assess the condition of fenders, identifying signs of wear and tear, and addressing issues promptly can significantly prolong their durability. Furthermore, cleaning fender surfaces regularly to remove contaminants and applying protective coatings can shield rubber compounds from degradation.

Utilizing Advanced Materials and Technologies

Innovations in rubber fender materials and technologies have revolutionized the industry, offering enhanced durability and performance capabilities. Investing in high-quality, abrasion-resistant rubber compounds and advanced design features can significantly improve the longevity of rubber fenders. Additionally, integrating technologies such as IoT sensors for real-time monitoring and data analysis can provide valuable insights into fender performance and maintenance requirements.

Best Practices for Prolonging Rubber Fender Lifespan

Regular Inspection and Maintenance : Conduct routine visual inspections and perform maintenance tasks to address any issues promptly.

Proper Storage : Store rubber fenders in a cool, dry place away from direct sunlight and harsh environmental conditions.

Training and Education : Ensure personnel are adequately trained in handling and maintaining rubber fenders to prevent damage.

Compliance with Manufacturer Recommendations : Adhere to manufacturer guidelines for installation, maintenance, and replacement of rubber fenders.

Conclusion

Maximizing the durability of rubber fenders is essential for ensuring the safety and operational efficiency of maritime facilities. By understanding the factors influencing durability, implementing proactive maintenance strategies, and leveraging innovative materials and technologies, professionals in the maritime industry can prolong the lifespan of rubber fenders and enhance overall operational performance. Remember, investing in the longevity of rubber fenders today can translate into long-term benefits tomorrow.

In conclusion, prioritizing the durability of rubber fenders is not just a sound operational practice but also a testament to a commitment to safety and efficiency in maritime operations.

Remember, the longevity of rubber fenders directly impacts the resilience of maritime infrastructure. By incorporating these strategies and best practices, professionals can ensure that their rubber fender systems remain robust and reliable for years to come.

Comments